Lifting Points by RUD.

Engineered for Safety, Performance, and Versatility.

In the field of lifting equipment and rigging gear, RUD lifting points are trusted for their outstanding safety, ergonomic design, and technical excellence. With more than 1,000 lifting point configurations, including bolt-on, weld-on, and quick-mount lifting points, RUD sets industry standards across sectors – from construction to energy, heavy manufacturing to offshore applications. Our portfolio also includes custom-engineered solutions tailored to your specific lifting and rigging requirements. For extreme environments, RUD provides specialized lifting points compatible with ROV (Remotely Operated Vehicle) subsea operations.

Built for safety.

RUD lifting points are manufactured to the highest global safety standards. Many of our hoist rings and swivel hoist rings are ASME certified, ensuring consistent reliability in the most demanding lifting tasks.

Key performance attributes:

- Working Load Limits (WLL) calculated under worst-case conditions for maximum safety.

- 100% crack testing of all load-bearing components.

- Minimum 400% breaking force.

- Designed for 20,000 load cycles with a 50% overload.

Whether you're handling heavy machinery or precision components, RUD’s advanced attachment points ensure secure, predictable performance.

Straight to the point – simple, convenient, safe: The new lifting point configurator from RUD.

Find the right lifting point for your specific lifting application quickly and easily. Various filter functions and animated 3D views ensure greater safety and the certainty that nothing has been overlooked. Share the results with your RUD expert or dealer and send an inquiry directly. In addition, you will receive valuable additional knowledge that will be available for your daily work.

FAQs

A lifting point is a critical component in any lifting equipment system. It serves as a secure attachment point between the load and the rigging mechanism, allowing for lifting, rotating, or moving heavy objects using cranes or hoists. These points come in various forms – such as hoist rings, swivel hoist rings, and eye bolts – and are engineered to connect with hooks, shackles, or slings to ensure safe and efficient load handling.

To ensure maximum safety during lifting operations, lifting points must be properly installed in accordance with the load characteristics and application requirements. For bolt-on lifting points, it is essential to verify that the load and base material are suitable for bolting.

The positioning of the lifting points should follow established rigging principles: single-strand attachments must be placed vertically above the load center; two-strand attachments should be located on both sides of the center of gravity; and for three- or four-strand configurations, the lifting points must be distributed evenly around the center of gravity. Regular inspection of bolt tightness, corrosion, deformation, and wear is critical to maintaining system integrity.

RUD lifting points are known for their outstanding safety features, high load capacities, and ergonomic design. All load-bearing components are 100% crack-tested to ensure structural integrity, and many models are capable of withstanding four to five times their rated Working Load Limit (WLL).

The portfolio includes bolt-on, weld-on, and quick-mount lifting points, with load capacities reaching up to 250 tons. In addition to robust mechanical properties, RUD products offer clear WLL markings, patented wear indicators, and highly visible powder-coated finishes – typically in magenta or pink – for easy identification on site.

Lifting points should be inspected regularly and before each use. Check for tight bolt fittings, signs of corrosion, wear, cracks in the weld seam, and any deformation. Regular maintenance helps ensure the safety and reliability of the lifting equipment.

RUD offers one of the most comprehensive and rigorously tested ranges of lifting solutions worldwide, with over 1,000 lifting point variants developed for demanding applications across industries. The brand stands for certified quality, engineering precision, and long-term reliability. Whether you require swivel hoist rings for dynamic loads or weld-on lifting points for permanent fixtures, RUD products are designed to maximize safety and reduce handling time. Backed by ASME certifications, extensive testing, and field-proven performance, RUD is the trusted choice for professionals who can’t afford to compromise.

Special features of RUD lifting points.

RUD has long been focusing on solutions for demanding lifting tasks. Many hundreds of application-specific products now make up the world's largest range of lifting points. Our modern and tested product solutions increase safety for people and loads as well as efficiency. They can also drastically reduce the handling times that are not included in any calculation.

The optimum solution for every application.

The RUD range includes hoist rings with a WLL of up to 250 t and weld-on variants with a WLL of up to 100 t. All load-bearing elements are 100 % crack-tested. They can withstand 4-5 times the WLL until they break. The bolt-on variants are powder-coated in the striking pink or magenta color. At many points, the RUD design engineers have integrated patented wear markers and there are clear markings showing the minimum WLL for the negative possible loading direction. The most common variants are tested by the responsible employer´s liability insurance association, and this is documented by a test certificate and a test stamp.

Bolt-On Lifting Points.

Due to their wide range of threads, bolt-on lifting points from RUD can be attached to almost any load. This makes them very flexible in use. RUD lifting points are designed for a dynamic load of at least 20,000 load cycles, they are tested at an overload of 50 %. Their WLL range from 100 kg to 250 t. The bolts on our lifting points for bolt-on connections are 100 % crack-tested. They offer quadruple safety in every loading direction. In addition, all the load-bearing parts have been crack-tested and load-tested.

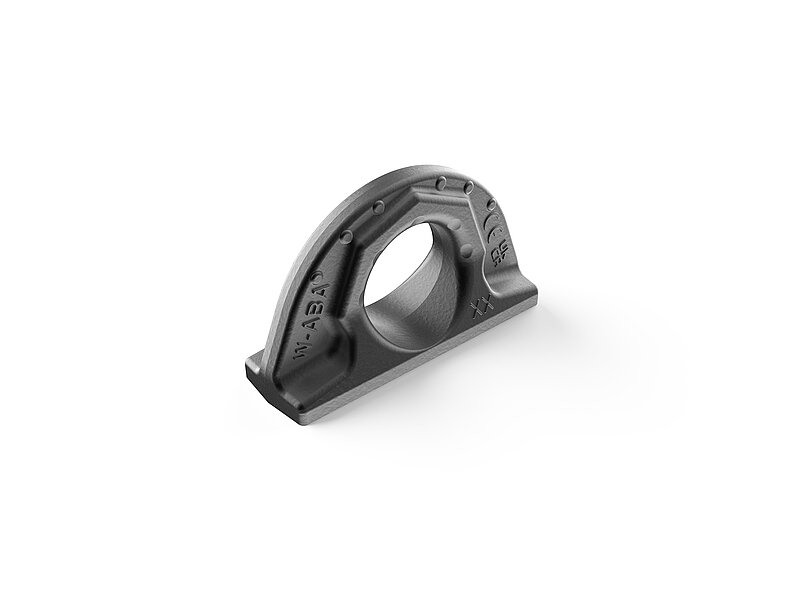

Weld-On Lifting Points.

RUD weld-on lifting points are designed for a dynamic load of at least 20,000 load cycles, they are tested at an overload of 50 %. Their WLL range from 630 kg to 100 t, allowing them to offer quadruple safety in every loading direction. In addition, all the load-bearing parts have been crack-tested and load-tested in accordance with EN 1677. RUD weld-on lifting points are suitable for every common welding process. The weld-on blocks consist of an easy to weld material and the suspension rings are made from drop-forged, high-strength quenched and tempered steel in lightweight construction.

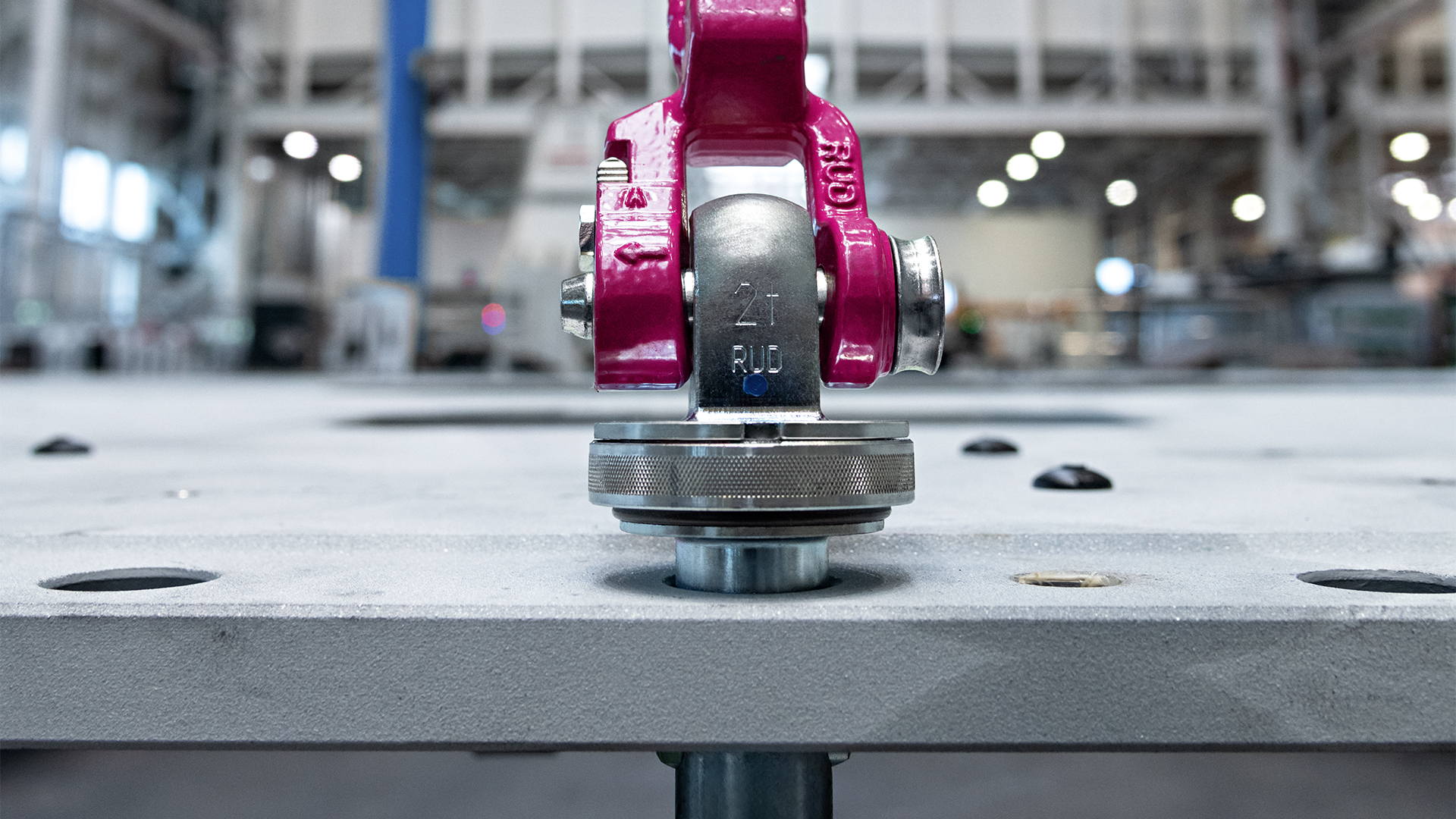

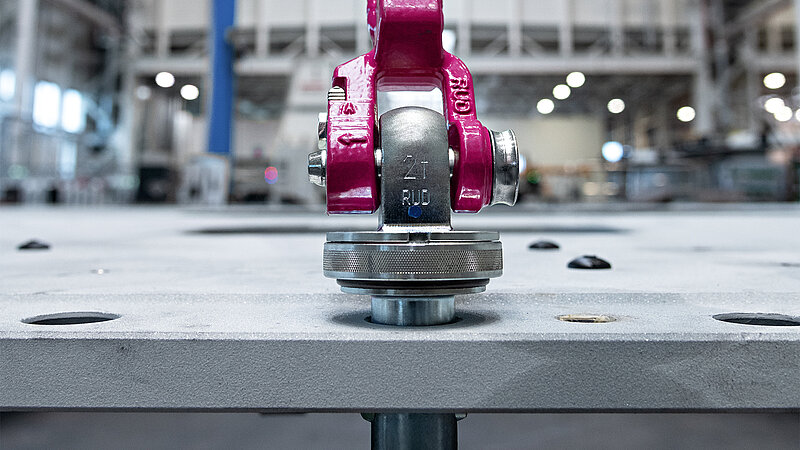

Quick-mount Lifting Points.

Quick-mount lifting points from RUD are the first choice wherever the same or similar components with through or undercut holes need to be lifted repeatedly – for example large flanges. Here, the lock nut would be difficult to reach on a bolt-on lifting point. Or it may not be possible to attach a nut at all – for example, if flanges are to be stacked.

Our quick-mount lifting points can be assembled and disassembled – compared to bolt-on variants – with time savings of up to 80 percent. And all without tools. Unlock, insert, lock, done: the handling advantages are enormous. In addition, the lifting points can be used variably in length and diameter within the defined range, so they do not have to fit exactly into the hole. Depending on the configuration, the WLL can reach up to 5 tons.

Rigid and rotating/swivel lifting points.

At RUD, you will find bolt-on and weld-on lifting points, which can in turn be subdivided into rigid and rotating/swivel lifting points. Rigid lifting points are ring bolts or weldable eyes. Because their pulling direction cannot be changed, they are primarily used in single-strand solutions. They must therefore not be flexible. The areas of application for rotating or swivel lifting points are usually multi-strand solutions. This is because the lifting points must align themselves in the direction of pull when the load is lifted in these applications. Rotating and swivel lifting points are therefore more flexible than rigid variants.

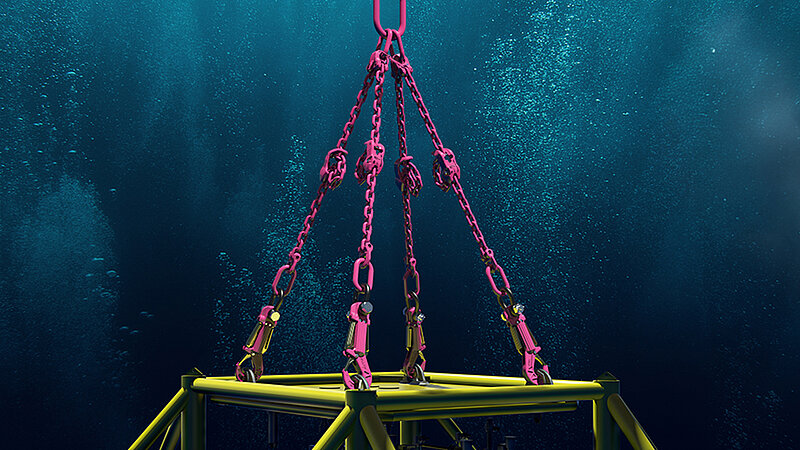

Your expert partner for marine and offshore assignments.

Challenging tasks in the maritime & offshore sector demand a lot of both people and equipment. The safe lifting and lowering of loads on deck and under water in depths of up to 3000 m, extreme ambient conditions, unpredictable currents and difficult lighting conditions at such great depths are all enormous challenges. Particularly when time windows are tight, and precision and safety are required.

As a successful innovator in the field of lifting, moving and lashing loads, RUD can also offer clear added value in the demanding maritime & offshore sector.

What is a chain suspension?

In the world of lifting means, chain suspensions form the connection between the sling and the load. They consist of several components. Chain suspensions can be purchased fully configured – depending on the weight, size and shape of the load.

Components of a suspension are:

- Master link

- Chain (in one or several strands)

- End component (e.g. a hook)

- Any connecting elements (to connect two chains)

- Any shortening elements (to shorten chains)

- Any further elements (e.g. balancer)

General selection criteria for lifting points.

- Determine the overall weight of the load.

- Then determine the number of lifting points to be used according to the possible installation position.

- In accordance with the operating instructions, observe the reduction factors resulting from the tilt angle, and the temperature influences.

- Select the correct lifting point according to the type of use with a WLL that exceeds the weight determined under point 3.

What does a risk analysis involve?

Before choosing a lifting point, always prepare a risk analysis, bearing in mind that:

- The lifting point should not have any sharp edges.

- The eyelet diameter must be suitable for the hooks being used.

- Wall thicknesses and edge distances must be selected such that the safety flaps on the hook are guaranteed to fold in.

- The suspension must be designed with 4-fold protection against breakage in any direction, as WLLs could occur in all conceivable directions during the manufacture, transport and assembly of the structure.

- Special colour coding must be present.

Important for design engineers.

Loads are lifted using lifting means (chains, cables or synthetic slings) or lashed on the truck during transport. The different numbers of legs and their angles of inclination result in a multitude of loads and stress directions in the lifting or lashing points. In particular, the WLL of lifting points changes depending on symmetrical or asymmetrical loads. The design of lifting points can be calculated using certain equations.

1-leg lifting process: load factor 1 (right-hand figure). The load can rotate, the lifting point twists open. Risk of falling! Choose a lifting point with ball bearing.

Asymmetrical loads.

You can install up to four lifting points on a structure, distributing them depending on the properties of the load. During installation, ensure that the load hangs straight when it is being lifted and, for example, does not tilt – if necessary, use special lifting means from the RUD range.

Caution: With an asymmetrical load and 2 lifting points one lifting point must bear the whole load (see figure). Load factor 1 (max. permitted angle of inclination taken into account).

Testing lifting points: what you should know and what to consider.

Lifting points are safety-relevant products. Therefore, please note that all lifting points must be tested at least once a year by an expert to determine their continued suitability. Tests must be conducted…

- directly after installation or welding,

- at intervals depending on the WLL on the lifting point,

- after damages and special incidents.

Important: check the lifting point for …

- a tight fit of the screws and the correct torque moment;

- completeness;

- complete, legible WLL information and the manufacturer’s mark;

- deformations on load-bearing parts such as the main body, the suspension bracket or the strap;

- mechanical damage, e.g. large notches, particularly in areas subject to loads;

- reductions in the cross section of > 10 % due to wear occurrence;

- heavy corrosion (pitting corrosion);

- damage to load-bearing parts and to the weld seam;

- the correct bolt size, bolt quality and bolt-in length;

- the functioning of and damage to the bolts and bolt thread;

- easy, shock-free rotation between the upper and lower parts.

Important: follow the instructions and information in the relevant operating instructions.

Contact the RUD Team!

Please use the contact form for further questions about our products and service features.

Our Team will be pleased to help you. Just call us or send us an e-mail.