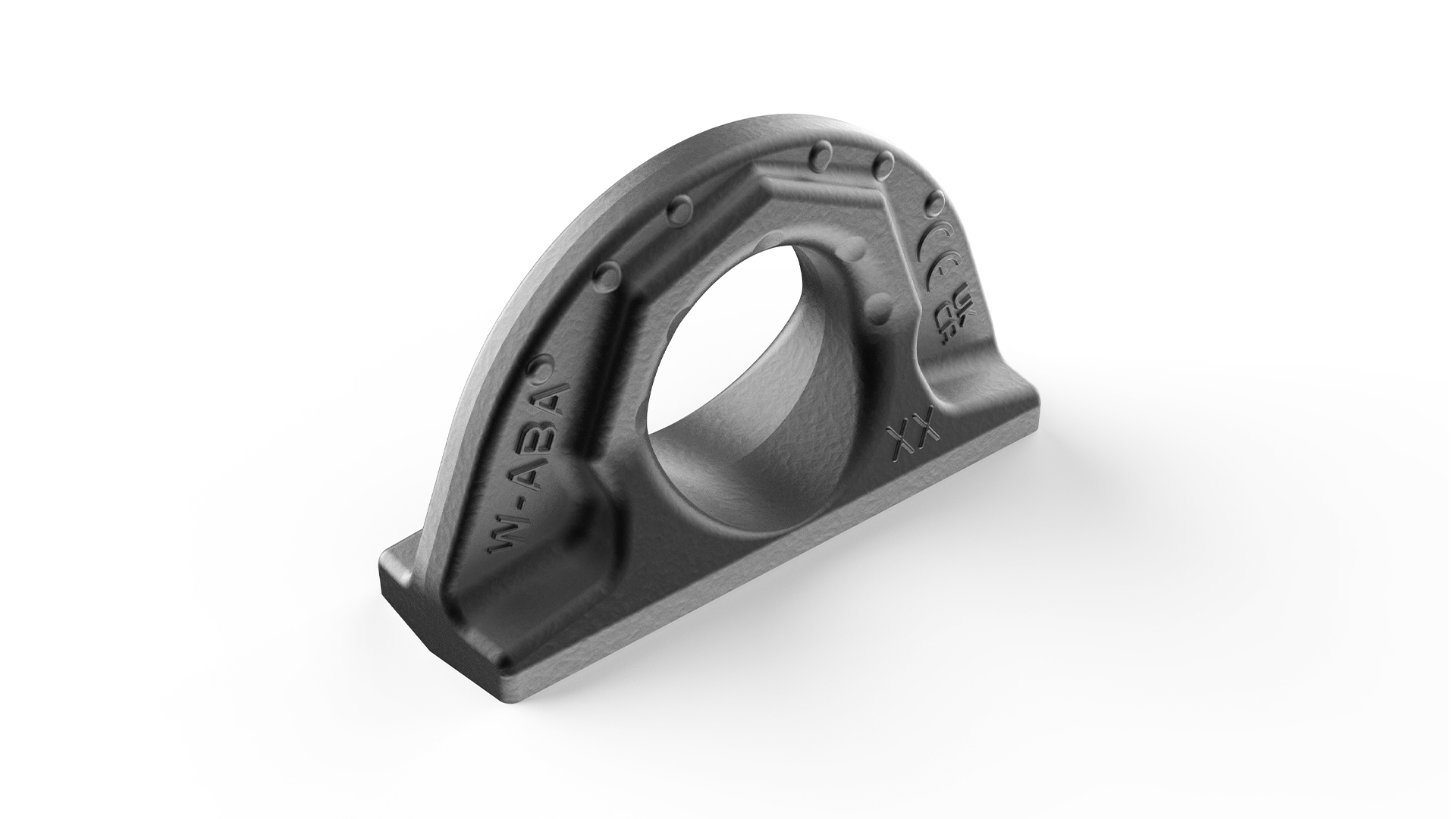

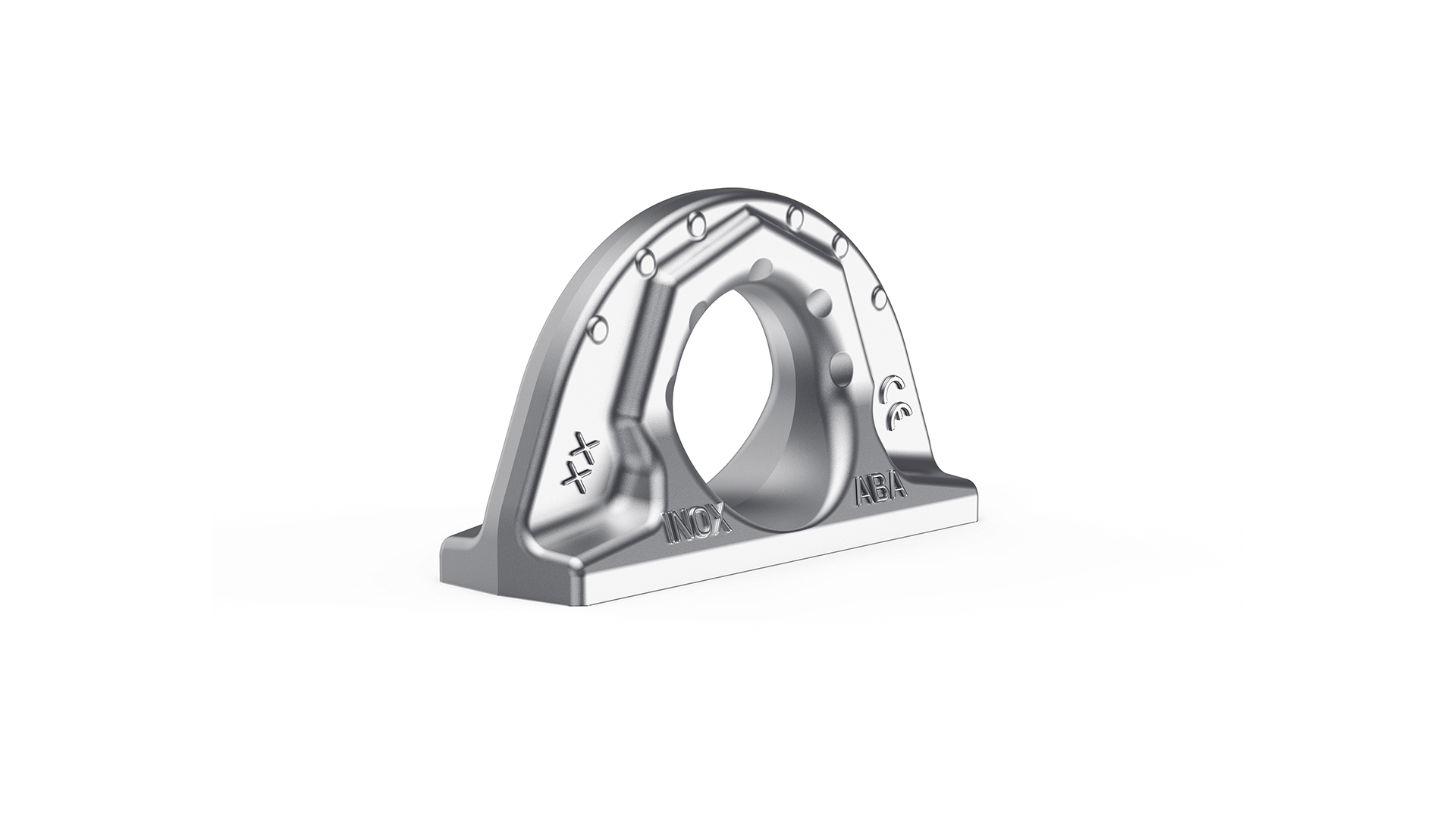

Weld-On Lifting Points.

Suitable for all common welding methods.

RUD weld-on lifting points are designed for permanent and secure integration into your load-bearing structure. These weldable load rings are compatible with all common welding procedures and offer long-term durability, making them ideal for applications where a permanent anchor point is required. As with all RUD lifting solutions, these lifting lugs are ASME certified and ready to perform.

Weld-on lifting points are used in approximately 25% of lifting applications. Since they are permanently welded to the load, they eliminate the need for removal after lifting – making them especially useful when loads must be rotated or repositioned multiple times. This fixed installation reduces the risk of human error and improves operational safety.

WLLs from 600 kg to

100 t – crack-tested.

RUD weld-on lifting points are engineered for dynamic use, withstanding over 20,000 load cycles and tested with 50% overload. The Working Load Limits (WLLs) range from 600 kg up to 100 tons. All load-bearing components are 100% crack-tested, ensuring fourfold safety in every direction.

To further support safe use, RUD has integrated patented wear indicators and clearly visible markings that indicate the minimum WLL in unfavorable loading directions. This makes these fixed rigging lugs especially reliable for complex lifting tasks.

Installation of Lifting Points.

Please observe the following guidelines for proper installation and safe use:

- Design the lifting point so that all applied forces can be safely absorbed by the base material without causing deformation.

- Ensure lifting geometry as follows to avoid misalignment, twisting, or unsafe loading:

- Single-strand attachment: Vertically above the load’s center of gravity.

- Double-strand attachment: Symmetrically on both sides of the center of gravity.

- Three- or four-strand attachment: Evenly spaced in one plane around the load’s center of gravity.

- Determine the required WLL per lifting point based on load symmetry and distribution.

- Avoid damaging the lifting lugs or pad eyes through sharp edges or improper contact with rigging equipment.

- Inspect lifting points regularly for proper torque on bolts (where applicable), signs of corrosion, visible wear, weld cracks, or deformation.

- Important: Welding must be performed by certified professionals according to applicable standards. Only use materials specified in the RUD user manual. All contact surfaces must be free from oil, paint, dirt, and other contaminants.

FAQs

Weld-on lifting points are permanently installed attachment devices used to lift, turn, or secure heavy loads. Unlike bolt-on lifting points, which can be mounted or removed as needed, weldable lifting points are permanently affixed to the load structure. This makes them a fixed rigging lug solution – ideal when high safety and permanent accessibility are required. Their immovable nature means they offer increased durability but reduced flexibility in terms of repositioning.

RUD weldable load rings are engineered for long-term use under high mechanical stress. They handle at least 20,000 dynamic load cycles and tolerate up to 50% overload conditions. Their WLL range from 100 kg to 250 t, and every unit is extensively crack-tested for maximum safety. Their robust design and patented wear indicators ensure reliable lifting performance under even the toughest operating conditions.

Weld-on lifting points from RUD stand out for their exceptional safety features. They provide quadruple safety in all directions and undergo 100% crack testing of all load-bearing elements. With clear WLL markings and patented wear indicators, these permanent anchor points meet and exceed industry safety standards – especially in applications where lifting precision and structural integrity are non-negotiable.

Yes, RUD weld-on lifting points can be used for a wide range of loads. Their wide Working Load Limit (WLL) makes them suitable for various lifting applications. The ability of these lifting lugs to handle dynamic loads and their extensive testing ensure they can be adapted to different lifting needs.

RUD weld-on lifting points are designed to be low-maintenance due to their robust construction. However, regular inspections are recommended to ensure they remain in good condition. Inspecting for any signs of wear or damage, especially after heavy use, is crucial. Ensure that all safety standards and regulations are followed to maintain the reliability and safety of the lifting points.

Contact the RUD Team!

Please use the contact form for further questions about our products and service features.

Our Team will be pleased to help you. Just call us or send us an e-mail.