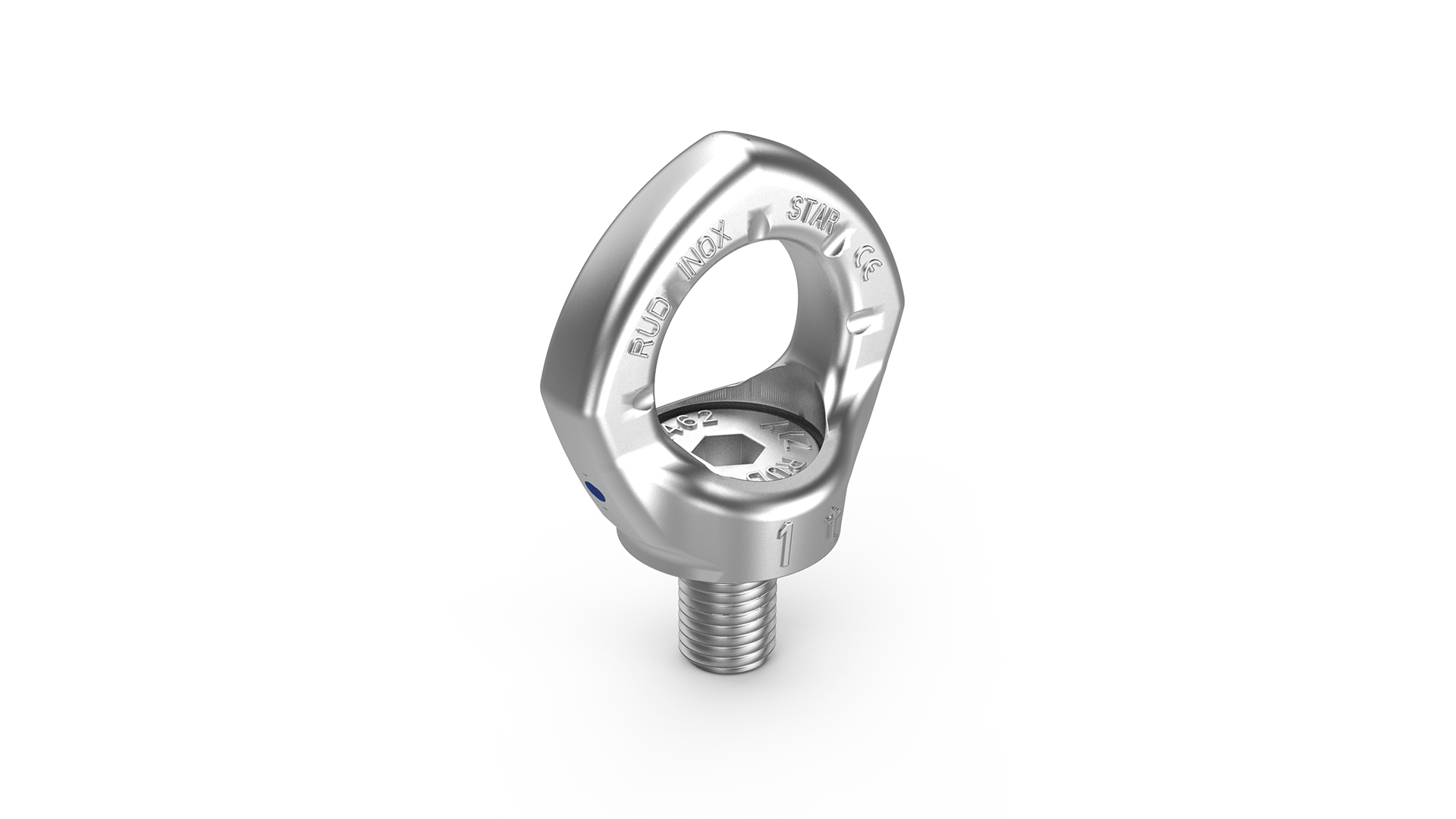

Hoist Rings – Bolt-On Lifting Points.

ASME Certified and Engineered for Demanding Applications.

With over 40 years of experience, RUD has consistently advanced the design and performance of bolt-on lifting points, also known as hoist rings. Engineered for dynamic loading of at least 20,000 cycles and tested with 50% overload, RUD hoist rings offer maximum durability and safety under real-world conditions.

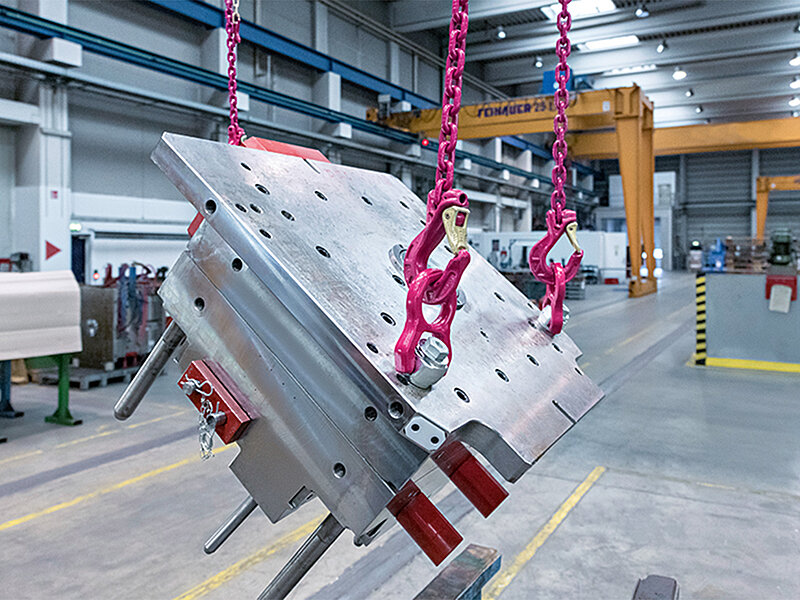

RUD bolt-on lifting points are designed for flexible use and fast removal. When lifting points are no longer required – or would interfere with downstream operations – they can be uninstalled with minimal effort. Thanks to a wide range of thread sizes, RUD’s pivoting hoist lugs can be adapted to almost any load geometry, offering true versatility in the field.

Wide WLL range – crack-tested.

RUD hoist rings are ASME certified and come ready for use, with Working Load Limits (WLL) ranging from 100 kg to 250 tons. Each bolt used in our bolt-on lifting point assemblies is 100% crack-tested to ensure safety in every direction of loading. The same rigorous testing is applied to all load-bearing components.

To support inspection and long-term safety, many models feature patented wear indicators, along with clearly marked minimum WLL values for off-angle loading. The familiar magenta or pink powder coating makes them easy to identify on busy worksites.

From the chain to the bolt.

RUD doesn't just lead in lifting points—we innovate across the entire load-handling system. Our in-house developed ICE lifting chain (Innovative Chain Evolution) offers higher performance with lower weight. An ICE chain can replace a Grade 8 chain of the next higher diameter, reducing dead weight by over 30% and significantly improving handling ergonomics.

Installation of Lifting Points.

Please follow these best practices when installing hoist rings or other 360° rigging hardware:

- Design the lifting point so that all applied forces can be safely absorbed by the base material without causing deformation.

- For bolt-on variants, ensure the load and base material are suitable for bolted installation up to the contact surface.

Avoid improper stress on the load by observing correct attachment geometry:

1. Single-strand: Directly above the center of gravity.

2. Double-strand: Above and on both sides of the center of gravity.

3. Three- or four-strand: Evenly distributed in a single plane around the load’s center of gravity.

- Ensure proper load symmetry by calculating the necessary WLL for both symmetrical and asymmetrical load setups.

- Protect lifting means from damage by avoiding contact with sharp edges.

- Regularly inspect hoist rings and attachment points for:

- Correct bolt torque Corrosion or excessive wear Weld seam cracks or deformations

- Important: Welding must be performed by qualified personnel in accordance with applicable codes. Only use approved base materials (refer to the RUD user manual). The mounting surfaces must be clean and free from oil, paint, or debris.

FAQs

Boltable lifting points, commonly known as hoist rings, are mechanical lifting devices that are mounted to a load using bolts rather than welding. This makes them highly adaptable and easy to install or remove, especially in setups where frequent repositioning or removal is needed. Unlike welded lifting lugs, they offer greater flexibility for temporary or variable applications.

While weld-on lifting points are fixed permanently to a structure, bolt-on lifting points can be mounted and unmounted as needed. This makes them ideal for use cases where lifting points may obstruct subsequent processing or must be repositioned for balance. Welded variants offer long-term stability, whereas bolt-on hoist rings shine in dynamic and adjustable lifting setups.

The key benefits of using bolt-on lifting points include ease of installation, high flexibility, and time-saving reusability. Since they can be removed without permanent modification to the load, they are especially useful for rotating or tilting tasks. This is particularly important when loads must be lifted from different angles or during multistage production processes.

Yes, hoist rings come in various configurations. Rigid types like eye bolts are suited for straightforward vertical lifts, while advanced models like the swivel hoist ring allow for 360° rotation and pivoting to align with the pull direction. These 360° rigging hardware solutions are designed to accommodate multi-leg lifts and reduce stress on the load, improving both safety and maneuverability.

When working with bolt-on lifting points, always ensure proper installation and load matching. The bolts must be tightened to the specified torque, and both the base material and contact surface must be appropriate for the application. Following manufacturer guidelines for WLL, thread engagement, and inspection frequency is essential to safe operation – especially in demanding or dynamic lift environments.

Contact the RUD Team!

Please use the contact form for further questions about our products and service features.

Our Team will be pleased to help you. Just call us or send us an e-mail.